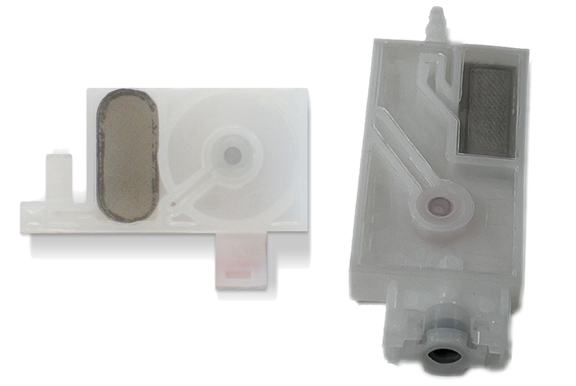

Dampers are deceptively simple-looking but critical components in the ink flow of DTG & DTF printers.

Dampers perform 4 functions.

- Provide a consistent ink supply reservoir for the printhead.

- Screen out any foreign material in the ink before it reaches the printhead.

- Act as a “pump”. There is round diaphragm behind the clear film side which has a spring behind it. As the printhead uses ink and the damper empties, the diaphragm gets pulled inward and starts compressing the spring mechanism. When the spring mechanism is pulled inward far enough, it eventually pushes back out, pulling ink in from the ink line and bottles.

- Dampen and regulate pressure changes in the ink line at the printhead as the printhead carriage rapidly stops and reverses direction while printing. When the carriage motion in one direction stops, the pressure momentarily increases and when it starts going back in the other direction, the pressure momentarily decreases, due to inertia. This is why the ink lines are not connected directly to the printheads. The dampers absorb these minor pressure deviations.

Damper failures can be caused by a number of things. The spring can start getting weak, so it doesn’t “pump” correctly. The O-ring that seals the connection to the ink line can start leaking air, resulting in banding or ink dripping from the bottom of the head. One of the clues you have a damper is failing is when the missing nozzles on your nozzle check prints keep moving around between head cleanings.

Not finding what you need?

You can contact our technical support team by sending an email to support@omniprintonline.com with your company name, contact name, phone number, printer serial number, and a quick description of how we can help you.

This will automatically open a support case for you in our ticketing system and a technical support rep will follow up with you shortly.