A grinding sound coming from your printer means that routine maintenance needs to be performed. We’ll cover some details about why this can happen and what type of maintenance, but first let’s run through a brief explanation of what causes the grinding sound.

What is Making that Sound?

A rubber drive belt connects the carriage drive motor to the print head carriage. This belt is firmly attached to the print head carriage, so if the motor is turning but the carriage can’t move, then the drive belt will slip on the motor’s cog. The grinding is the sound of the drive belt slipping across the motor’s cog.

Read on to see two reasons why the carriage may not move properly when the motor is engaged and how to resolve them both.

Ink Build-Up In the Pump

Ink build-up in the pump is the most common cause of grinding, due to the carriage being stuck in its docked position. Fortunately, it is easy to prevent by diligently cleaning the capping station and wiper blade areas of the pump, which is part of the daily maintenance routine — that is, the maintenance that should always be performed at the conclusion of any printing day.

How is it that ink in the pump can keep the carriage from moving?

Before directly answering that question, it’s helpful to understand that the pump does more than the obvious work of pumping. It’s set of gears and the related electronics also control rotation of the wiper blade, raising and lowering the capping station, as well as raising and lowering the carriage lock arm.

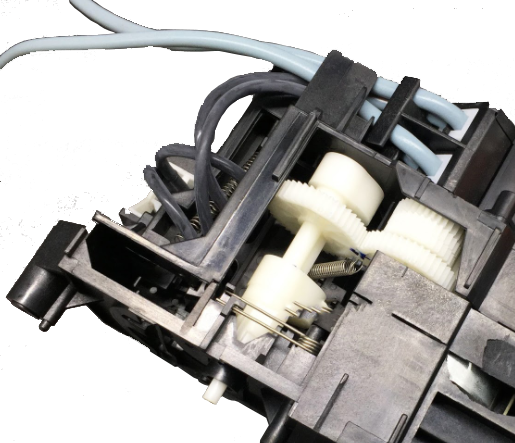

Bottom view of the pump mechanism, exposing gears for wiper blade & carriage lock arm movement

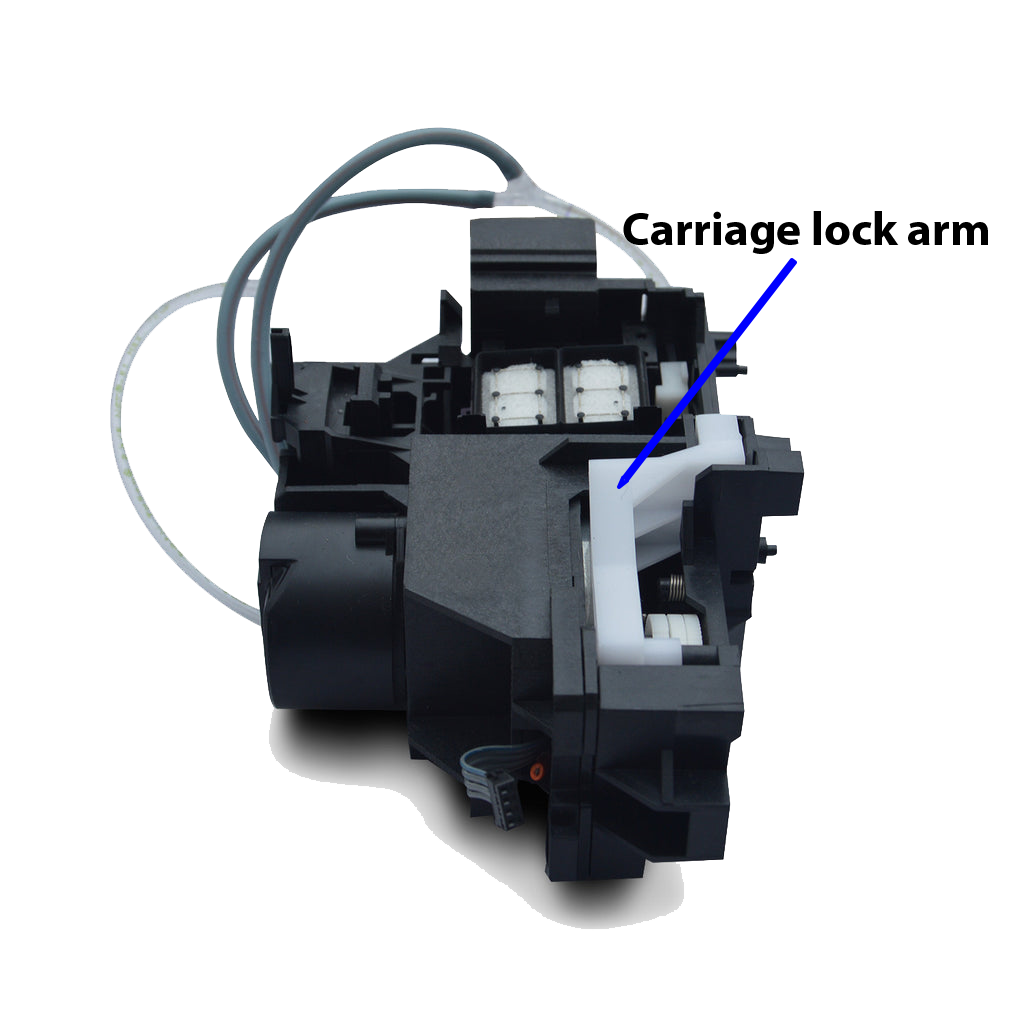

The carriage lock arm is in the left-rear section of the pump (when viewed from the front of the gantry.) When raised, the lock arm protrudes into a slot on the carriage assembly, locking it into position and preventing movement of the carriage until the lock arm is lowered.

Top of pump, viewed from the rear

Now, with the understanding that the pump includes a set of gears and other moving parts (the wiper blade, capping station, and carriage lock arm), we can understand that it’s not the ink that flows through the pump when priming or running head cleans that can lead to the grinding sound. Instead, it’s ink that can gradually drain down from the wiper blade area and down into the gears inside the pump.

This is one reason why the daily maintenance of the wiper blade and capping station areas are so important — to prevent the long-term drainage of ink down into the gears that control the movement of the carriage lock arm.

If you hear the grinding sound, do a thorough cleaning of the wiper blade and capping station area (see the below video for details), then reset the printer from its main power switch in the rear. If that doesn’t resolve the problem, proceed with cleaning the encoder strip.

A Dirty or Damaged Encoder Strip

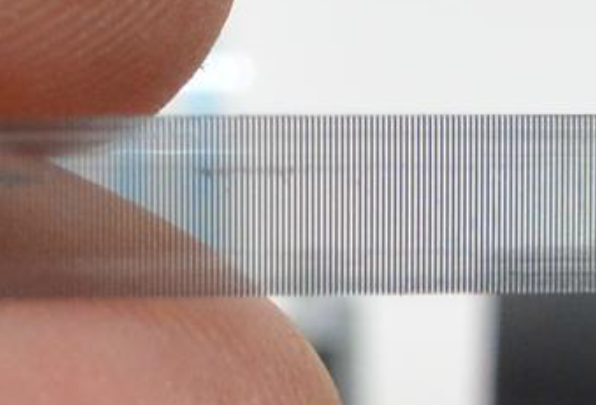

The encoder strip provides a sensor on the printer’s carriage with necessary guideposts for keeping track of its horizontal position. These guideposts are in the form of thousands of tiny vertical lines running along the full width of the carriage, from left to right.

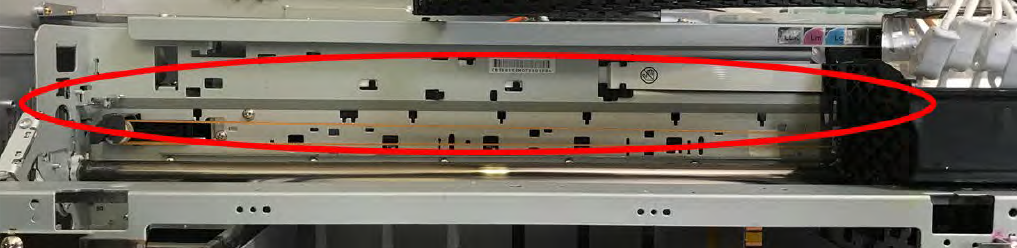

The encoder strip appears to be grey from a distance

A closer view of the encoder strip reveals that it’s transparent plastic with thousands of vertical lines

If the encoder strip becomes dirty then the printer may not be able to gauge its position accurately, and this can also result in the carriage belt grinding due to continuing to drive the carriage to the right after it has already reached its home position.

Cleaning the encoder strip is part of the routine weekly maintenance for Freejet 330-series printers, so your User Manual has detailed instructions on the procedure, beginning on page 31. (See links to the Freejet 330-series manuals below.) After thoroughly cleaning the encoder strip, turn the printer’s main power off for a few seconds from the rear switch, then back on.

If the grinding occurs again very shortly after performing the pump and encoder strip maintenance tasks referenced above, please contact Technical Support for further help.

Not finding what you need?

You can contact our technical support team by sending an email to support@omniprintonline.com with your company name, contact name, phone number, printer serial number, and a quick description of how we can help you.

This will automatically open a support case for you in our ticketing system and a technical support rep will follow up with you shortly.