OmniPrint recommends cleaning the encoder strip and cleaning & lubricating the carriage rail on a bi-weekly schedule (every two weeks). As both procedures involve moving the carriage to the left, it makes sense to do them both at the same time.

Aside from the bi-weekly schedule, it’s advisable to also perform both tasks if you ever note inconsistent horizontal registration in your prints.

Watch the below video or read the following detailed instructions and stay on top of these two easy maintenance tasks to keep your Omni DTF Mini reliably printing at maximum quality.

Video Demonstration

The Encoder Strip

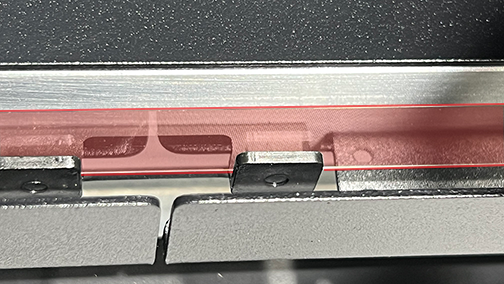

The printer’s encoder strip is a long, narrow, semitransparent plastic tape which spans the full width of the printhead carriage’s travel path. It’s covered with tiny vertical lines which are seen and counted as the carriage moves back and forth. The printer knows the exact location of the carriage at any moment based on its count of the encoder strip’s vertical lines as an offset from the carriage’s “home” position.

The Omni DTF Mini encoder strip is positioned behind a two-piece (left & right) protective shield which helps to prevent most vaporized ink and other particles in the environment from getting onto the encoder strip, but this won’t prevent it from needing to be cleaned on a regular basis.

Supplies for maintaining the encoder strip

- 70% isopropyl alcohol

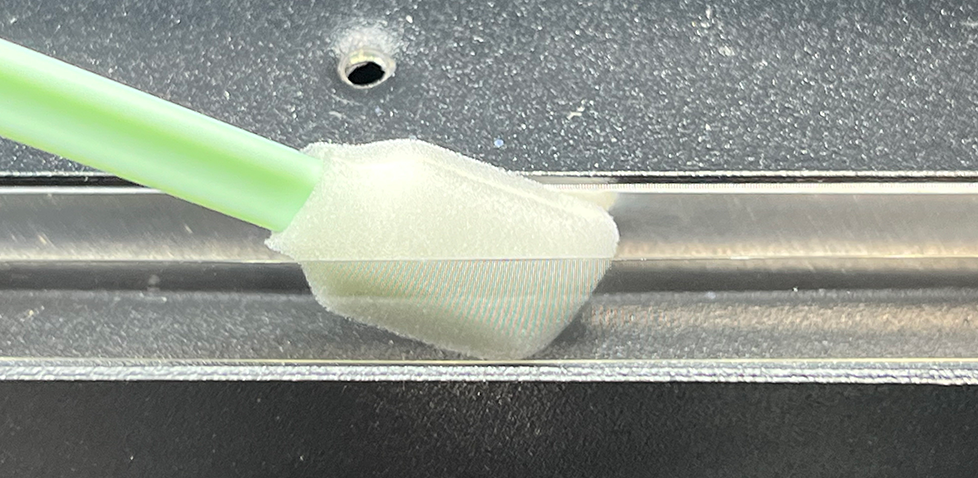

- microfiber cloth or foam swabs

Cleaning the encoder strip

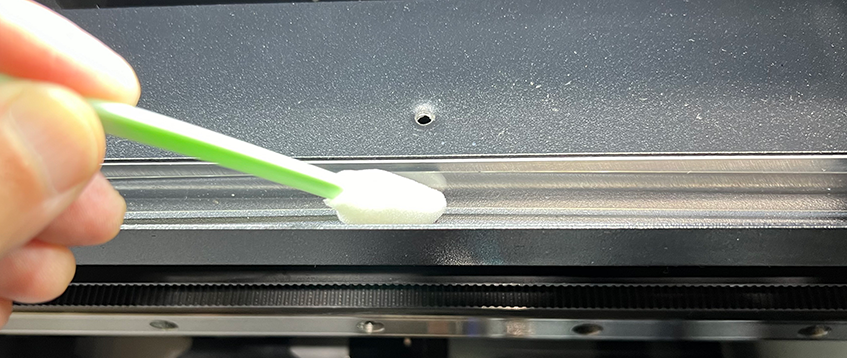

Wet a microfiber cloth or foam swab with 70% isopropyl alcohol and gently wipe both sides of the exposed section of encoder strip to the left of the carriage.

Move the carriage to its full-left position to expose the part of the encoder strip that the carriage was previously covering. Clean that additional section of the strip, then home the carriage using the printer’s Enter button or the Omni DTF Mini UI software’s Home button.

The Carriage Rail

The printhead carriage rides along a rectangular rail, gripping the grooves at the top & bottom of the rail. It’s important to keep the rail clean and lubricated to prevent excessive drag on the carriage motor and to maintain smooth operation and optimal horizontal registration.

Supplies for maintaining the carriage rail

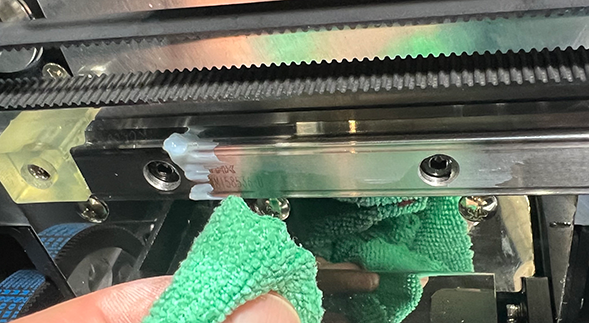

- Clean, lint-free cloth (microfiber recommended)

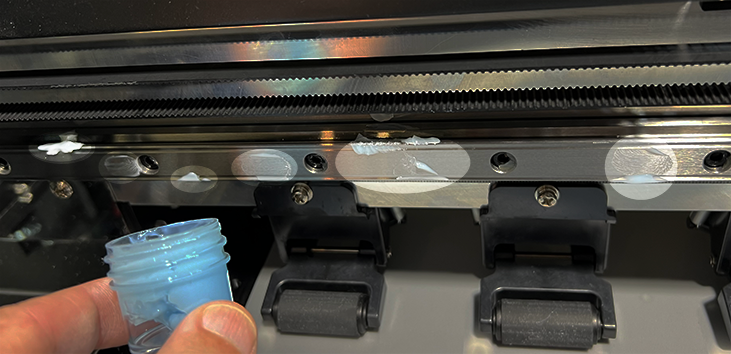

- Blue grease (FreeJet grease, OmniPrint part # FJG7G)

Cleaning & lubricating the carriage rail

No chemicals should be used to clean the carriage rail, and no lubricant except the blue “FreeJet” grease referenced above.

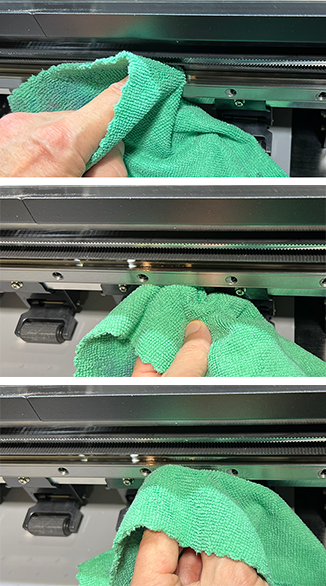

To clean the carriage bar, simply wipe down the exposed top, front, and bottom surfaces with a clean, dry cloth.

To lubricate the carriage bar, put a few dabs of blue grease across the same surfaces that were wiped down when cleaning the rail.

Move the carriage to its full-left position to expose the part of the carriage rail that it was previously covering. Clean and lubricate that additional section of rail, then use the carriage movement controls to run the carriage back & forth across its full range of travel to distribute the grease across the rail.

Finally, wipe off any excess grease that may build up at either end of the rail.

Home the carriage using the printer’s Enter button or the Omni DTF Mini UI software’s Home button.

As always, be sure to wet cap the printer if you won’t be using it.

Not finding what you need?

You can contact our technical support team by sending an email to support@omniprintonline.com with your company name, contact name, phone number, printer serial number, and a quick description of how we can help you.

This will automatically open a support case for you in our ticketing system and a technical support rep will follow up with you shortly.