The below video demonstrates how to replace dampers in a Freejet 330-series printer. For step-by-step text with photos, see the Installing Freejet Support Kit Parts article.

Topics: Maintenance

Testing Freejet Ink Flow through Dampers (video)

The below video demonstrates how to test dampers in a Freejet 330-series printer for clogging and air leaks, including:

- Removing the damper cover plate (Damper Panel, p/n P-BR1012).

- Removing a damper (p/n P-DM1000).

- Physical inspection of a damper.

- How to manually draw ink through a damper using a syringe.

- How to identify a clogged or punctured damper, or a damaged O-ring (p/n P-SC1000).

How to Shut Down & Wet Cap the OmniDTF with No Power and No PC

Introduction

As mentioned in the OmniDTF System Shutdown article (linked at the bottom of this page), performing proper maintenance and wet capping the printer when shutting it down is critical to maximizing the service life of your printheads, capping stations, and wiper blade.

The process detailed in that article requires using the OmniDTF UI software to wet cap the printheads after completing the shutdown maintenance. Moving the carriage away from its home position can be done from the printer’s control pad or the OmniDTF UI program.

But what if you experience a power failure or your PC has lost its ability to communicate with the printer for some reason?

In the below video and the following instructions, we explain how to manipulate the capping station platform and the carriage to allow performing shutdown maintenance and wet capping the printer manually in the event of a power failure or any situation that prevents normal use of the controls and software.

Demonstration video

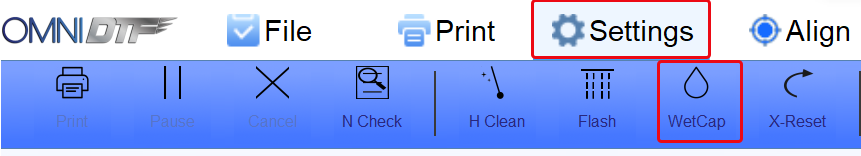

Your PC Can’t Wet Cap the OmniDTF

If you have not lost power and the printer’s control panel is working fine but you can’t complete the wet cap process from the OmniDTF UI software on your PC for any reason, follow the usual shutdown procedure until it’s time to click on the software’s WetCap icon. At that point, follow the instructions near the end of this article for Manually Wet Capping the Printheads.

The Printer Has No Power

If you have lost power, first make sure the Emergency button hasn’t been accidentally depressed by rotating it about ¼ turn clockwise. That will release the button and restore power if it had been depressed.

If the Emergency button was not depressed, either power is no longer being provided by the outlet or the printer’s power system needs troubleshooting. In either case, we want to ensure that the printer’s carriage will not move if power is restored while you’re working on it by turning off the printer’s power switch. Optionally, you can also unplug the power cable.

The Dust-Curing Machine’s master Power switch or its oven’s ‘Curing’ switch (for power to the oven) should also be turned off, to prevent it from coming back on while potentially unattended when power is restored.

Manually Releasing and Undocking the Printhead Carriage

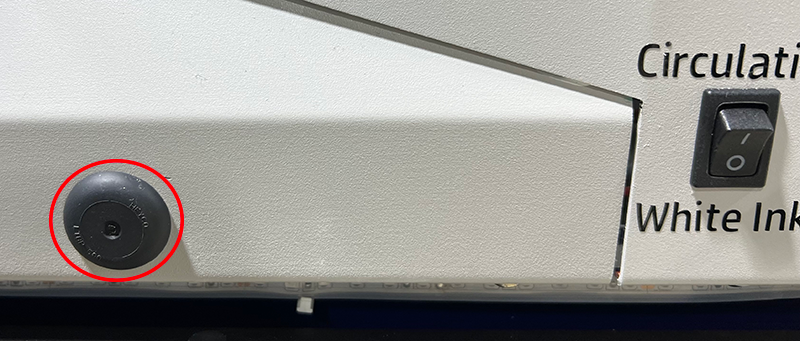

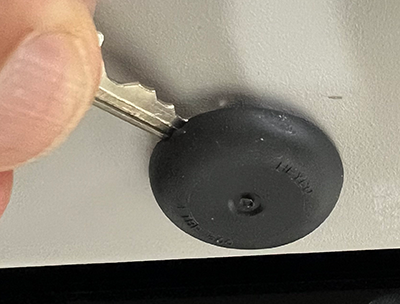

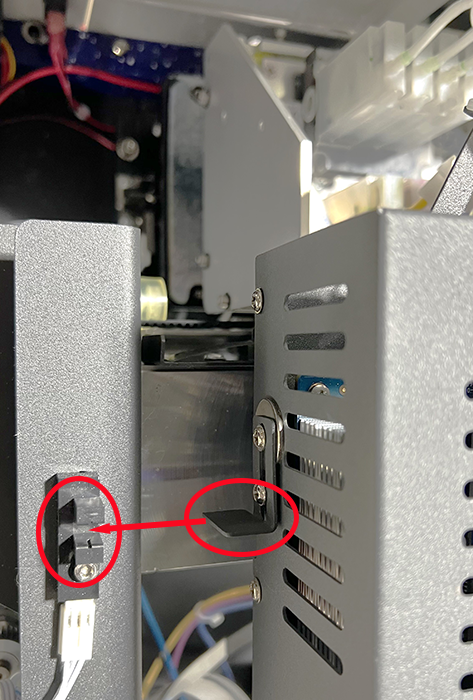

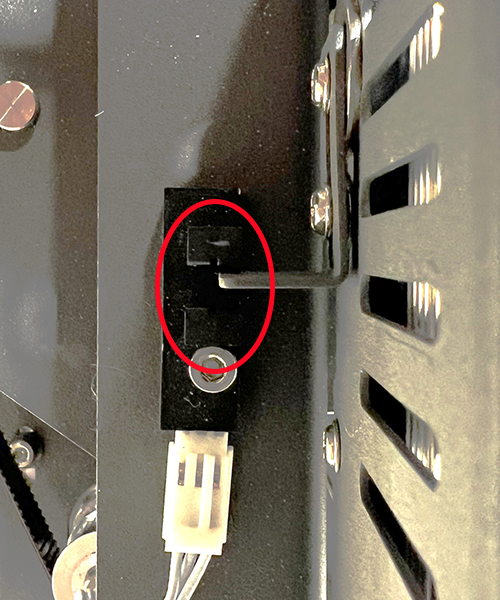

- Remove the small, black rubber plug covering a hole below the printer’s control pad and locate the screw head on the other side of the hole(s) exposed by removing the plug(s).

- Identify whether the head of the screw in your printer has a Phillips or Allen-type head.

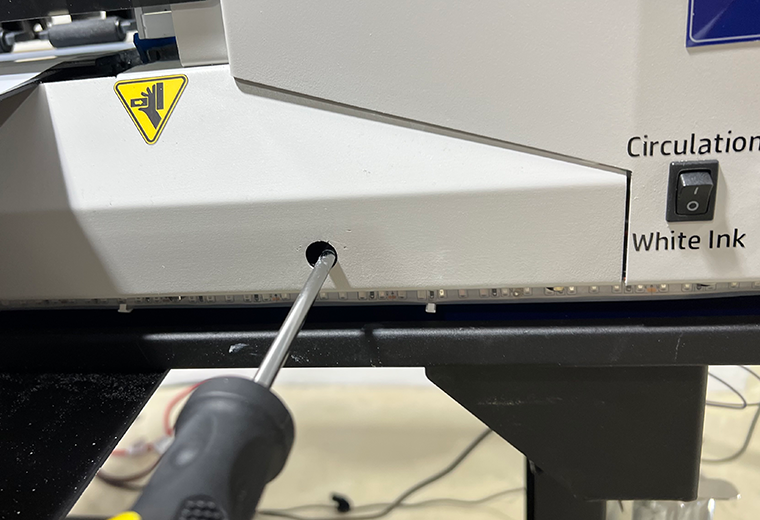

- Rotate the screw counterclockwise to lower the capping station platform until it can turn no further in that direction.

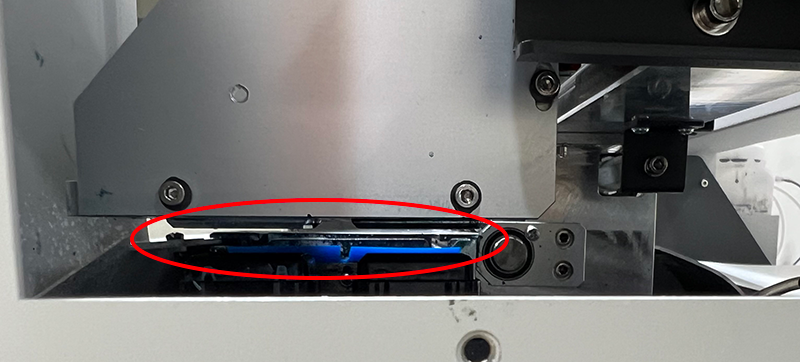

- After the capping stations are fully lowered, manually push the carriage to its fully leftward position to perform the routine shutdown maintenance.

With the carriage at its full left position, you can now perform all of the routine shutdown maintenance steps.

Manually Putting the Carriage in its Home Position

The printhead carriage’s Home position is not its fully-right position. That would be too far right and the nozzle plates and capping stations may not be properly aligned.

Use the metal tab on the right side of the printhead carriage and the slotted sensor on the carriage frame to find the Home position. The correct carriage position is when its tab reaches the assembly’s sensor window, at the mid-point of the slot.

Position the carriage so the end of the metal tab just reaches the center of the sensor’s gap.

Manually Wet Capping the Printheads

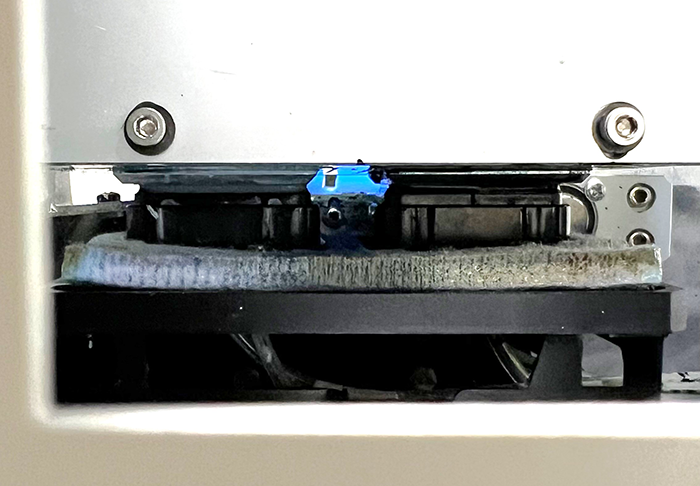

At this point, you should have already performed the shutdown maintenance, filled the capping stations with Super Cleaner, and moved the carriage to its Home position. If not, do that now before continuing.

- Remove the black rubber plug(s) under the printer’s control pad, if you haven’t already done so. (See steps 1 & 2 in the Manually Releasing and Undocking the Printhead Carriage section above.)

- Use a Philips head screwdriver or Allen wrench (depending on the screw head behind the exposed hole) to rotate the screw clockwise while looking through the opening made by removing the right side window to watch the capping station platform rise.

- Continue rotating the screw until the capping station presses against the bottom of the printhead, then raise it about another 1/4″ or so to compress the capping station seals against the printhead plate.

The printer is now properly shut down and wet capped when the above steps have been completed.

If you haven’t already done so, this is a good time to empty the waste ink bottle and confirm that all of the ink clips are closed.

OmniDTF System Shutdown

Properly shutting down your OmniDTF printer is very important to ensure that it will be ready to print the next time you start it up. Fortunately, the process is very easy!

Take about 10 minutes to go through these simple steps when you’re finished with your print jobs.

Click the Related Articles link at the bottom of this page if you are experiencing a power outage, printer hardware issue, or PC connectivity problem preventing you from following the instructions below.

Curing Oven Shutdown

If you haven’t already done so, start by turning off the Curing Oven’s main power switch. This is a master switch that will cut power to the Duster, Shaker, and Oven — so shutting off any other switches is optional.

Printer Shutdown Maintenance & Wet Capping

See the below video demonstrating the OmniDTF printer shutdown maintenance and wet capping processes, or read the following description.

Demonstration video

Step-by-step instructions

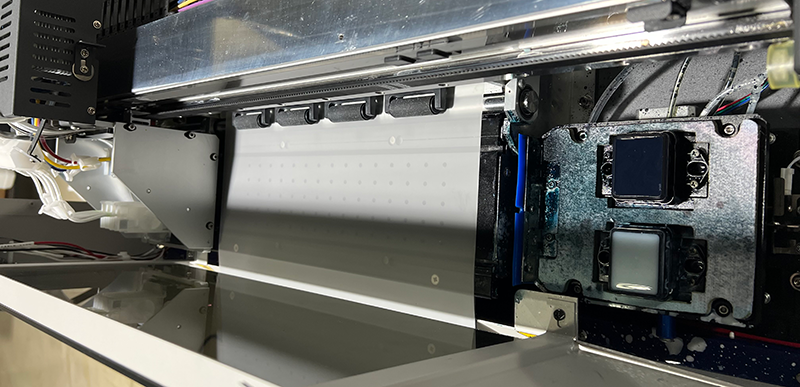

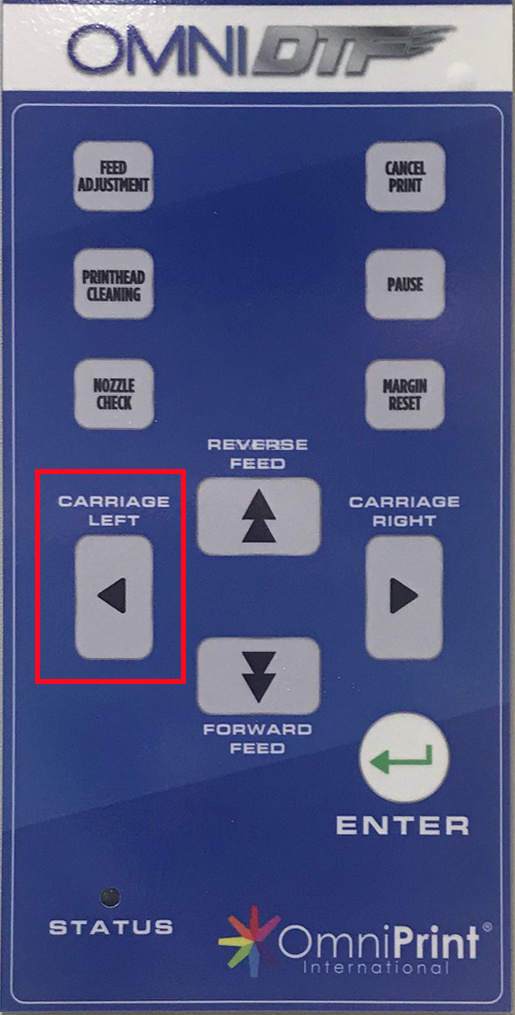

- Press and hold the Carriage Left button until the printhead carriage is in the center of its range of motion to ease access to the ink clips and expose the capping stations and wiper blade.

- Clamp all 8 of the ink line clips shut.

- Use the Carriage Left button again to move the printhead carriage to its full-left position.

- Wet an anti-static foam swab or a clean, lint-free cloth with Super Cleaner to thoroughly clean:

- The full length of the wiper blade

- The rubber seals surrounding both capping stations

- Remove any bits of dried ink on the capping station sponges or seals with tweezers.

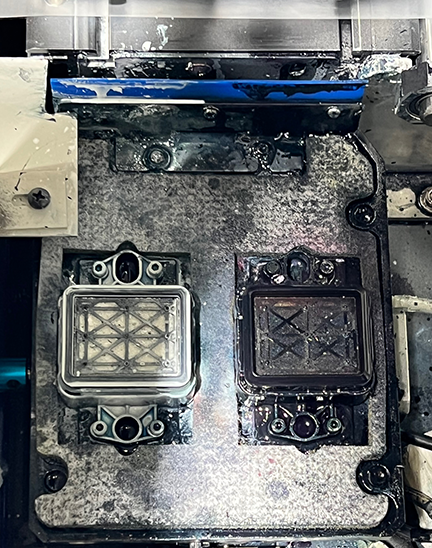

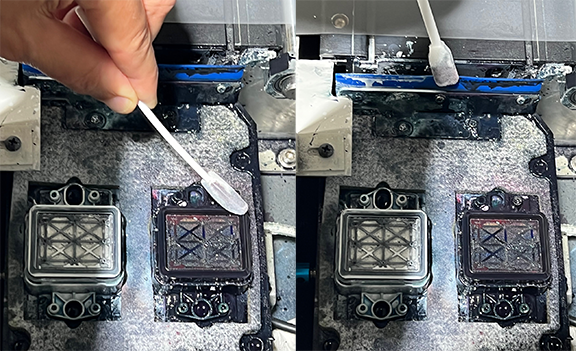

The remainder of the steps before wet capping the printhead are all about keeping the printhead mounting plate and the side edges of the printhead nozzle plates clean. If these areas are allowed to accumulate ink then eventually the dried ink will hang down below the printhead and leave streaks on the film.

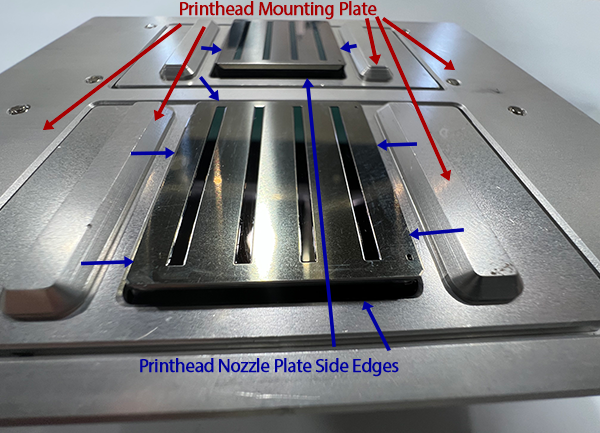

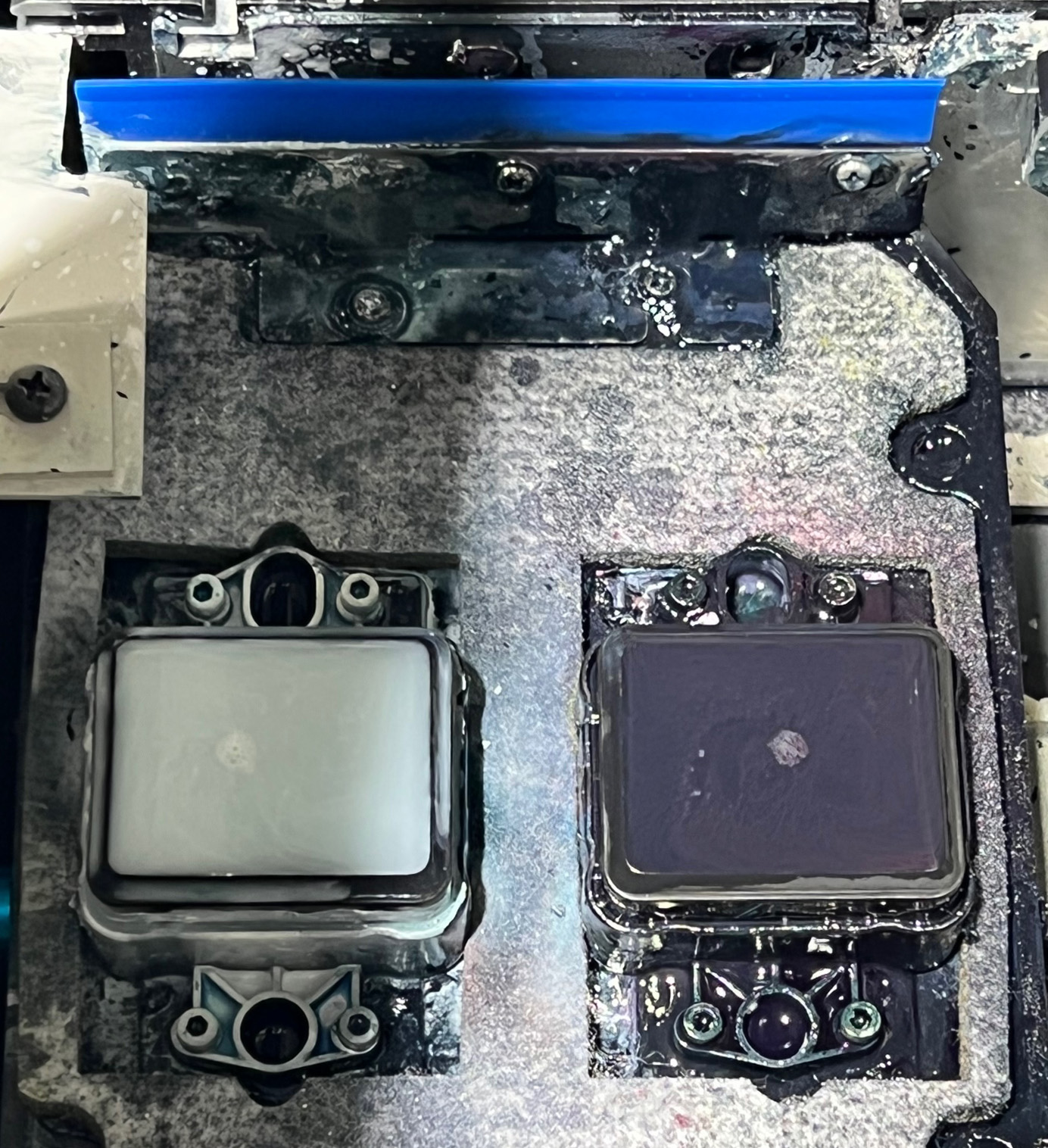

Before continuing this maintenance process, please note the following images of the shape and relationship of these parts to each other, and examples of how they may appear before and after cleaning.

Area of printhead mounting plate and nozzle plate edges to be cleaned.

Bottom of printhead mounting plate with printheads installed. Red arrows point to areas of the mounting plate; blue arrows point to the nozzle plate side edges

Areas of the printhead nozzle plate cleaned by the wiper blade, not manually

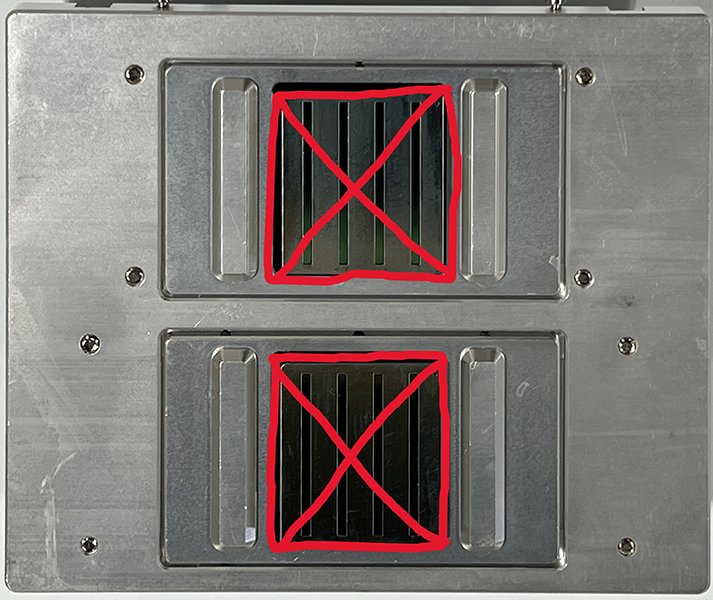

Red X’s mark the face of the nozzle plates, an area that we don’t clean manually.

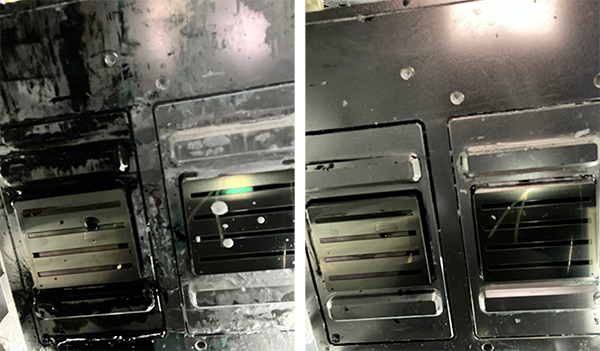

Before & After examples of dirty and clean mounting plates and nozzle plate edges

Cleaning the mounting plate and nozzle plate edges daily prevents ink buildup.

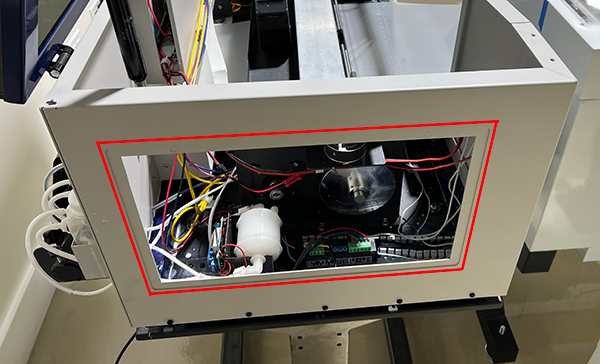

Now that you’re familiar with the area we’ll be working with, let’s proceed with cleaning the mounting plate and the side edges of the printhead nozzle plate. - Remove the left-side window to access the chassis interior’s left side.

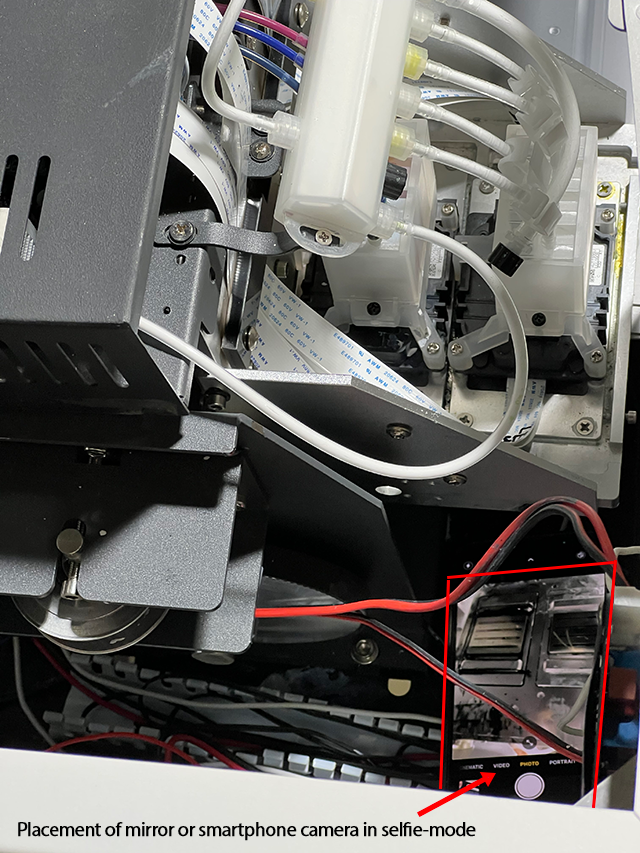

Left side of OmniDTF printer with the window panel removed. - Place a mirror or smartphone camera in selfie-mode inside the front-left corner of the printer chassis, tilted at an angle to provide you with a view of the printhead plates and their mounting plate, which face downward on the bottom of the printhead carriage, to orient yourself and get your hand into position to begin cleaning the area.

Top-down view of a smartphone in selfie-mode tilted at an angle to display the printhead mounting plate and the printhead nozzle plates. - Use a clean, lint-free cloth dampened with Super Cleaner to reach under the printhead carriage and wipe any ink from the mounting plate and the side edges (only) of the printhead nozzle plates.

- A foam swab can be used to clean the area at the front of the white ink printhead if a cleaning cloth wrapped around a finger won’t fit in the space.

- If contact with the printhead’s nozzle plate is made accidentally, dab the contacted area with Super Cleaner on a clean, lint-free cloth before wet capping.

Wet Capping the Printhead

- Fill both capping stations to the brim with Super Cleaner.

The wiper blade and capping station seals should now be free of any ink build-up and the capping station sponges completely submerged in Super Cleaner, up to the top of their seals. - Click the WetCap button under the Settings tab in the OmniDTF Windows program.

This will send the printhead carriage to its docked position and raise the capping station seals to press against the bottom of the printhead plate, bathing it in Super Cleaner within an air-tight seal.

The printer can now be turned off from the power switch on the right side, near the back of the printer.

The printhead maintenance components have now been cleaned and the printhead is wet capped.

Prepare for Success

We recommend two more steps to wrap up your shutdown process by preparing your printer in advance for the next day of printing.

- Empty the waste ink bottle for a fresh start next time the printer is used.

- Agitate the white ink to mix any separating pigment and prevent sediment from collecting in the bottom of the white ink bottles.

- Press a clean cloth or finger against the ink bottles’ breather hole to avoid spillage.

- Shake the bottle aggressively for 15-30 seconds to thoroughly mix the ink.

- When finished, use a clean cloth to wipe away any ink that appears to be blocking the breathing holes in the center of the bottle caps.

We can also shake the white ink during the startup process, and will want to do that if the printer has been idle for several days. However, shaking the white ink will result in small bubbles forming so we need to wait at least 15-30 minutes after shaking before circulating the white ink or printing.

If using the OmniDTF nearly every day, shaking the white ink at the end of a printing day, rather than at the beginning, helps to keep the pigment mixed while not delaying the startup process next time we want to use the printer.

That’s all there is to it. Your printer is now well-maintained and ready for your next day of printing.

Cleaning the Freejet Encoder Wheel

About the Encoder Wheel

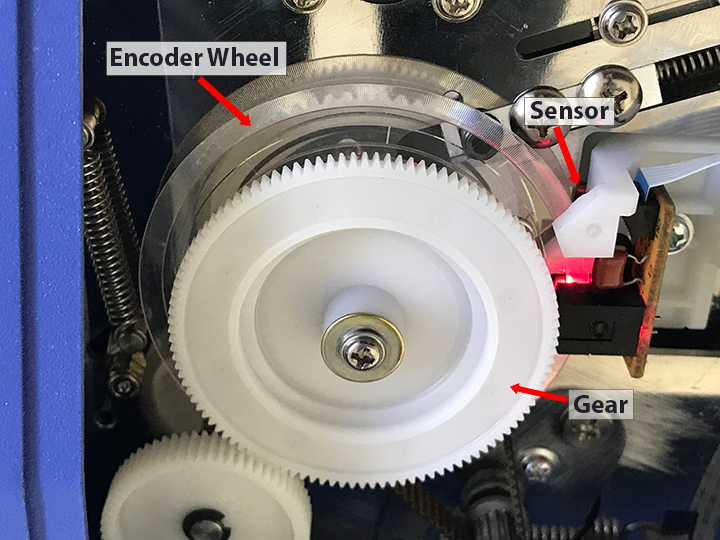

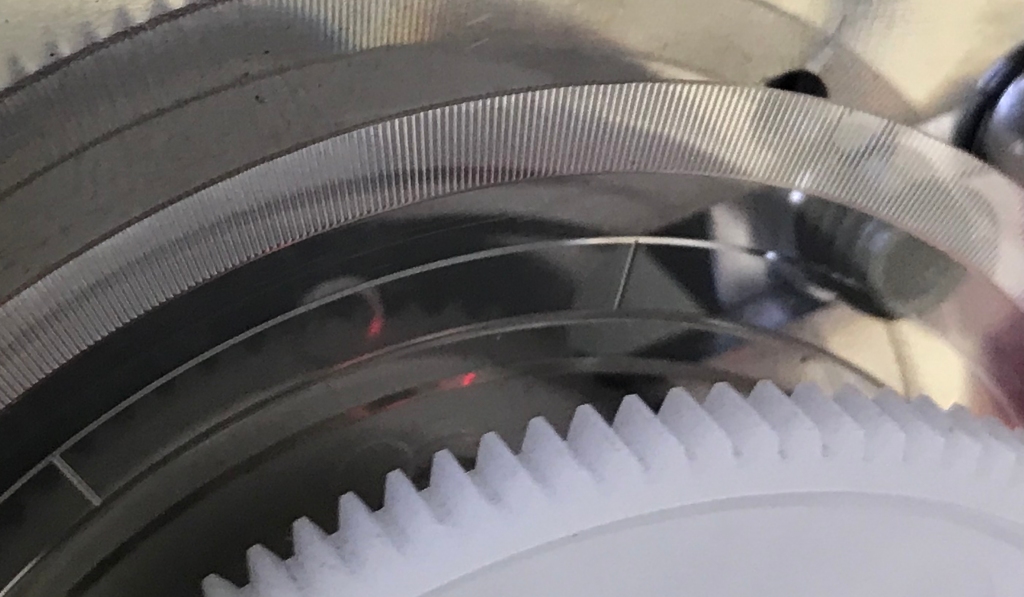

The encoder wheel is a semi-transparent disc that rotates in sync with the movement of gears that drive the gantry of Freejet printers forward and backward.

Tiny lines are etched around the outer 1/4″ or so of the wheel and these lines are read by a sensor and communicated to the printer’s control electronics to monitor and control the gantry’s position, relative to its rear or home position.

The encoder wheel is positioned far enough away from the print head carriage’s range of travel that it is unlikely to be affected by ink overspray and is normally protected from settling environmental debris by the gantry cover. Since it is largely isolated from debris in most environments, it generally only needs to be cleaned if you note problems with the vertical registration of prints — in other words, only if you note distortions in the vertical (top to bottom) dimension of prints.

Cleaning the Encoder Wheel

The below video demonstrates how to clean the encoder wheel in the Freejet 330-series of DTG printers.

Never use tools that could scratch the surface of the encoder wheel, since any scratches may be read by the sensor as false information about the gantry position, requiring that the encoder wheel be replaced.

Monthly Maintenance: Freejet 330-series (video)

There are two maintenance tasks that should generally be performed on a monthly schedule: carriage bar cleaning & lubrication and resetting the waste ink pad counter.

Cleaning & lubricating the carriage bar

This video demonstrates and explains how to properly clean and lubricate the carriage bar.

Resetting the waste ink pad counter

Resetting the waste ink pad counter is done 100% in software. The details on performing that aspect of the monthly maintenance are available here.

Weekly Maintenance: Freejet 330-series (video)

This video demonstrates and explains how to properly clean the encoder strip.

Remember to use only 70% isopropyl alcohol and a lint-free cloth or paper towel for the cleaning procedure. Use of any other cleaning fluid or agent may damage the marking on the encoder strip, requiring that it be replaced.

Daily Maintenance & Wet Cap: FJ330-series (video)

This video demonstrates and explains the importance of cleaning the print head brackets, undercarriage, capping station seals, and wiper blade, along with how to properly flush out the capping station sponges and wet cap the printer.

This both helps to keep the white ink well-mixed and also counters development of sediment from collecting in the bottom of the white ink bottles. Press a clean cloth or finger against the ink bottles’ breather hole to avoid spillage and shake the bottle aggressively for 15-30 seconds to thoroughly mix the ink.

When finished, use a clean cloth to wipe away any ink that appears to be blocking the breathing holes in the center of the bottle caps.

Maintenance Log Sheets

Performing the recommended maintenance is the most important factor in maximizing your equipment’s service life and consistently getting high-quality prints.

We recommend using the daily, weekly, and periodic maintenance log sheets for your printer and pretreatment machine (PDF download links below), to help you and your staff track and manage your equipment maintenance schedules.

Consistently performing the recommended steps at the beginning and end of each printing day will go far to prevent interruption of your production work that could otherwise occur due to insufficient maintenance.

Staying on top of the daily, weekly, and other periodic preventative maintenance also helps to maximize the service life of the equipment and protect your warranty.

How To Reset the Waste Ink Pad Counter

Resetting the Waste Ink Pad Counter

See how to reset the waste ink pad counter in the below video or the following step-by-step instructions.

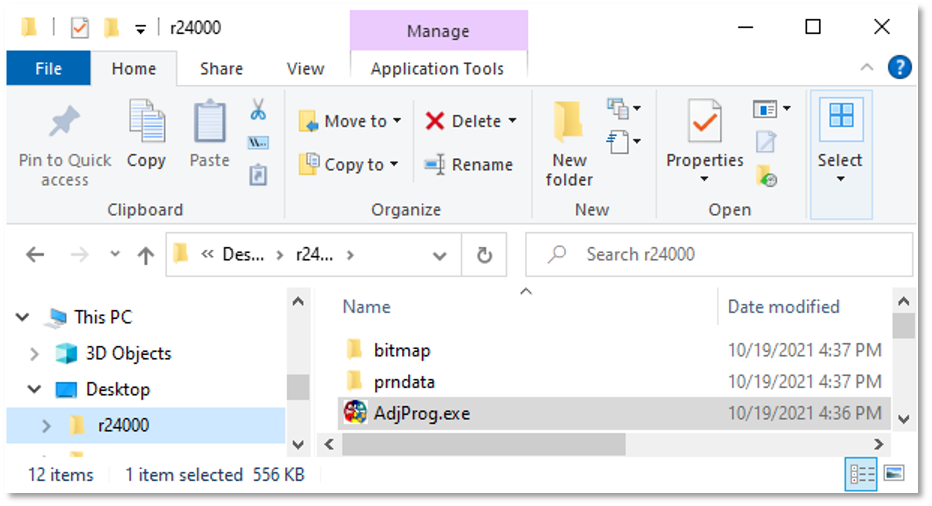

- Use Windows File Explorer to navigate to where you installed the Adjustment Program, then double-click on the AdjProg program’s icon to launch the Adjustment Program.

If you don’t already have the Adjustment Program on the PC connected to your Freejet printer, you can get it and find installation instructions here.

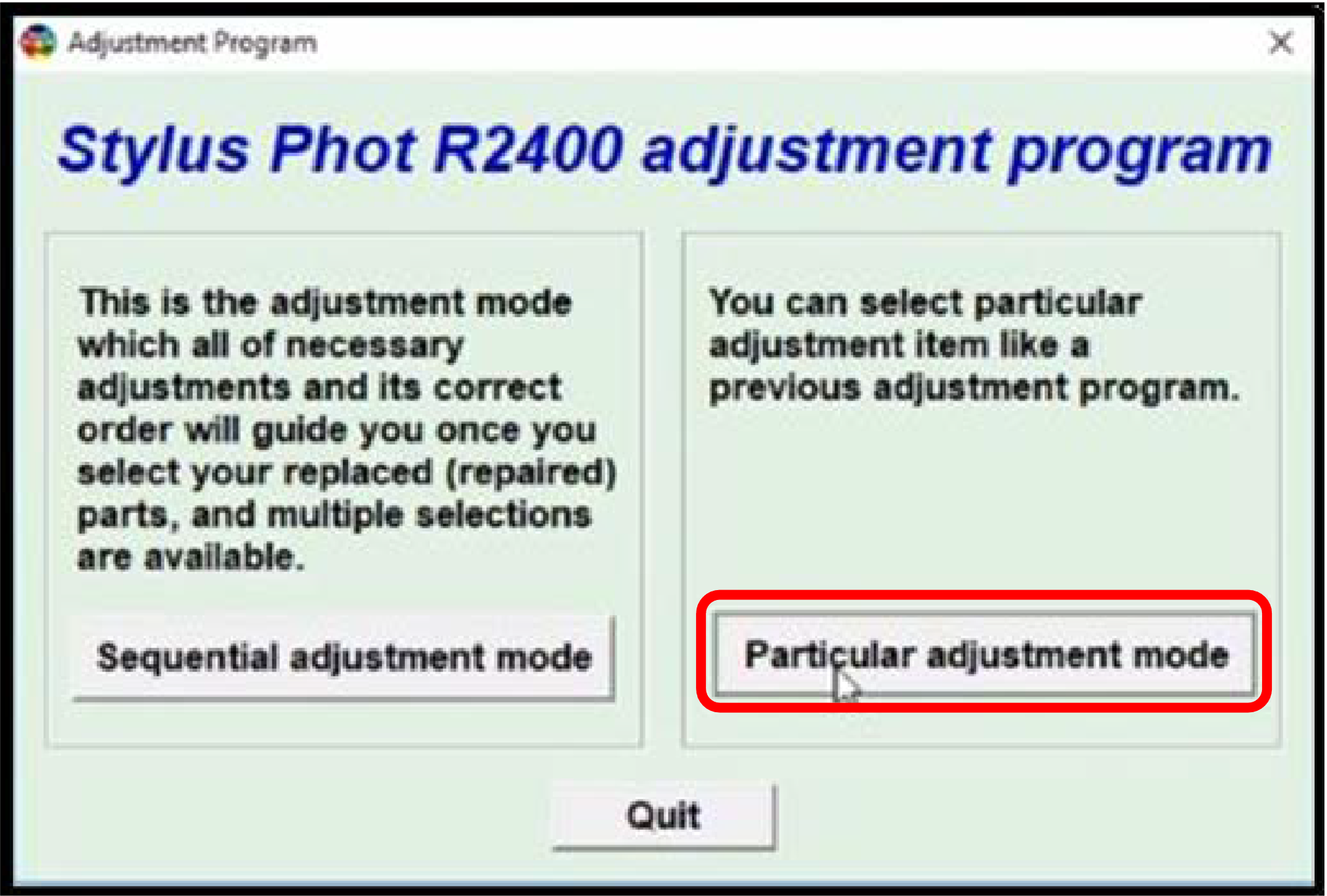

- Click on the ‘Particular adjustment mode’ button.

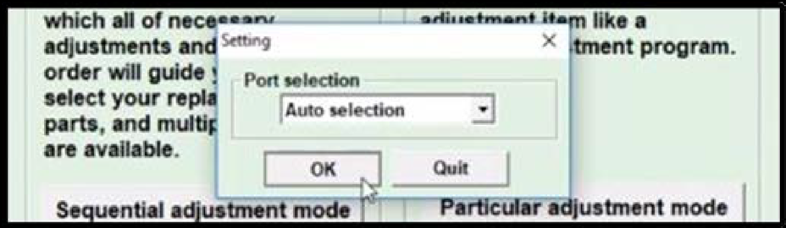

- In the pop-up window, confirm that the Port selection is set to ‘Auto selection’, then click ‘OK’.

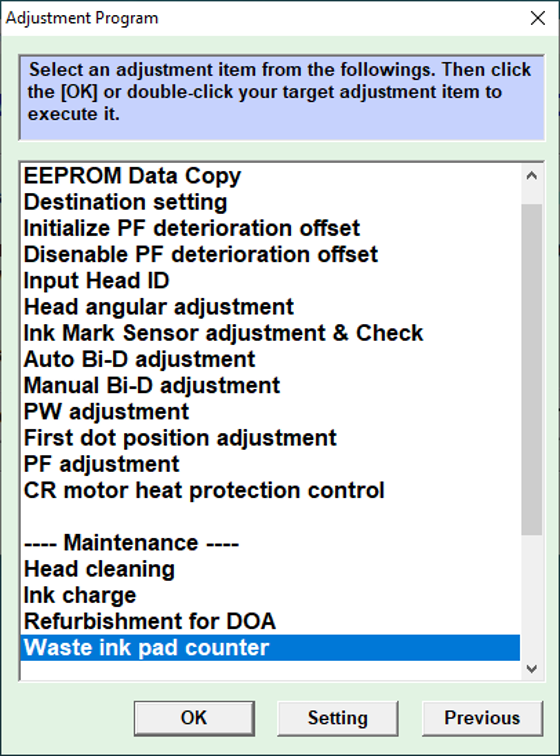

- When the Adjustment Program window appears, scroll down to the ‘Maintenance’ section and select ‘Waste ink pad counter’, then click on the ‘OK’ button.

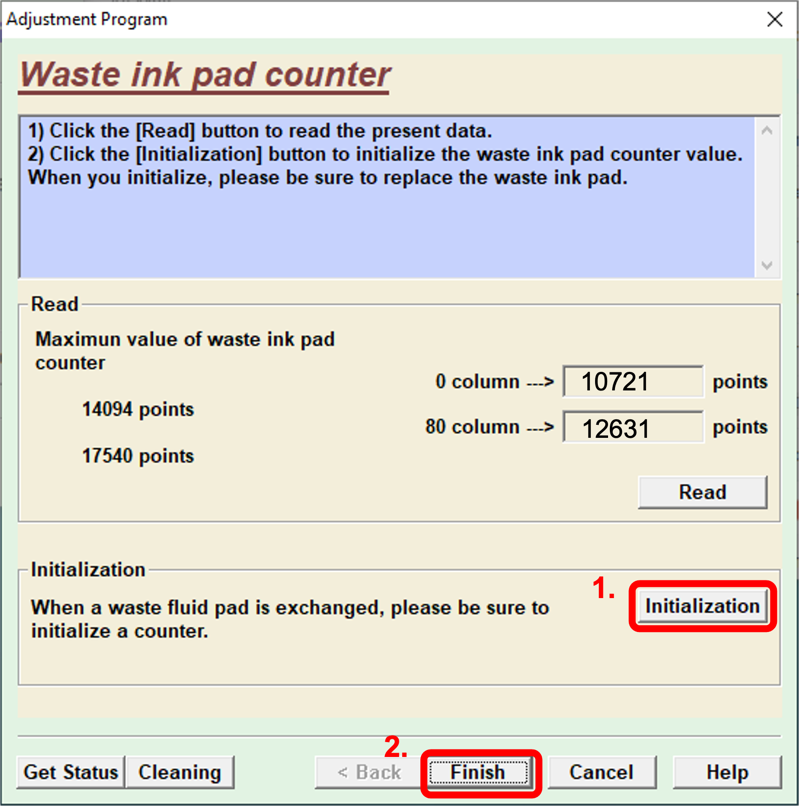

- Click on the ‘Initialization’ button to reset the waste ink pad counter, then click ‘OK’ to close the informational window which pops up, then click ‘Finish’.

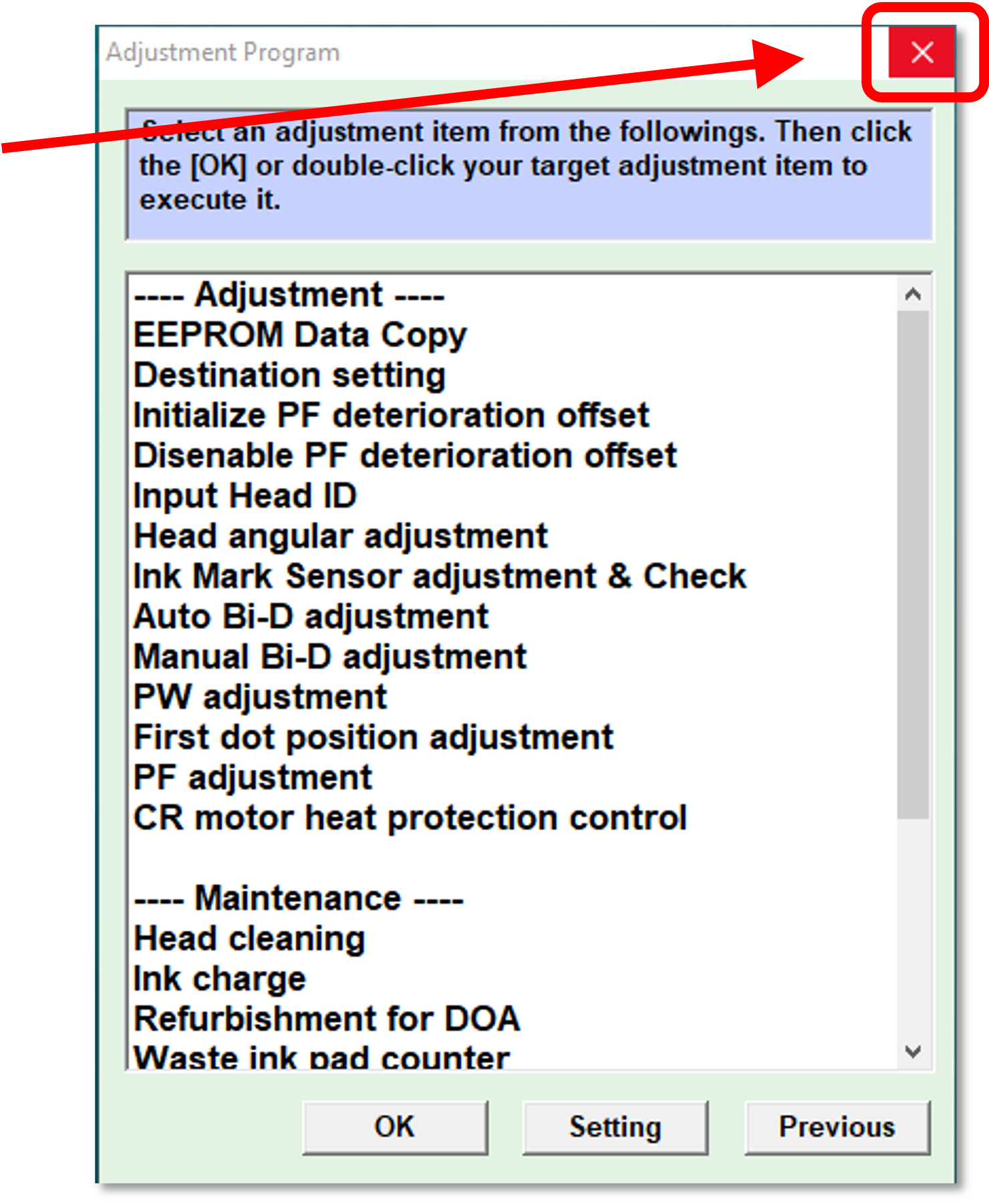

- Click the ‘x’ in the upper-right corner of the Adjustment Program’s menu screen to close that window.

- Click on the Adjustment Program’s ‘Quit’ button to end the program.

- Turn the printer off from the rear power switch, wait 5 seconds, then turn it back on.

Congratulations! The waste ink pad counter has now been reset.

Error Condition Requiring a Waste Ink Pad Counter Reset

If a waste ink pad counter reset isn’t performed on a routine basis, the ‘Error’ and ‘Ink’ lights on the control pad will eventually begin flashing — blinking in an alternating pattern. Once this has occurred the printer will no longer accept print jobs until we acknowledge and clear the error, using the procedure detailed above. But there’s no need for that to happen.

Rather than wait for this to happen, we proactively check the waste ink tank level visually to avoid overfilling, and we use the Adjustment Program to reset the counters which trigger the error condition. By doing this as part of routine maintenance, we avoid ever having a print job interrupted by the error condition.

The absorbent waste ink pad at the bottom of the waste ink tank should be replaced once it is thoroughly saturated. This waste ink tank is the chrome, rectangular box at the left end of the printhead carriage. See our article about replacing consumable parts for details on how to replace the pad.